Efficiency is important, whilst the agility and ability to adapt to complexity and continuous change is one of the greatest characteristics of supply chains fitness, and business success.

Often the speed of disruptions, and interdependencies, produce new dynamics that require leaders and teams to hone new skills and cultivate a continuous learning mindset to stay up to date with industry trends and best practices.

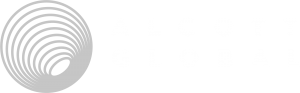

Framing the challenges is the first step, and with the help of over 300 executives, we ranked the top pressing issues in the supply chain industry over the next 12 months. There is no surprise that the top of the list is taken by concerns that have a direct and quick impact on the bottom line, forcing the supply chain leaders to find strategic short and long-term plans to maintain the robustness of their value chains.

The survey took place in May 2023, and 50% of the respondents have listed Talent Shortage as one of the challenges they see. In a previous article, we attempted to go beyond the buzzwords and list down the hard skills that are in high demand as well as the essential soft skills that the respondents have identified as being the most impactful. Having a holistic end-to-end understanding of the supply chain, while striking a balance between being adaptable and at the same time influential, are a few highlights of the recommendations, and we encourage the readers to have a look at the detail in the article titled Be Your Success Story: Skills and Narrative in Supply Chain.

I. Supply Chain Challenges over the next 12 months

In this white paper, we will focus on the other challenges, highlighted by the respondents of the survey and some strategies to address key concerns.

Let’s revisit the most pressing issues, according to the respondents of the survey:

1. Changes in geopolitics, Trade policies, and Customs regulation

Geopolitical tensions can lead to trade disputes and embargoes, while trade policies and customs regulations affect costs, supply chain routes, and documentation requirements.

These factors can cause uncertainty and volatility in the industry as these changes may disrupt global trade flows, introduce barriers for businesses, and impact market dynamics. These unpredictabilities make long-term planning and supplier relationships extra challenging for supply chain managers.

2. Rising Inflation and Increasing Labor Costs

The combination of geopolitical turmoil and economic uncertainties has resulted in a surge in inflation, leading to increased costs for essential components of the supply chain, such as raw materials, transportation, and labor, resulting in companies facing mounting expenses throughout their operations.

Factors such as wage inflation, labor regulations, and competition for skilled employees, at all levels, contribute to increased expenses.

Based on circumstances, forecasts, and economic dynamics, the leaders will need to be as strategic as possible, in employing cost-reduction strategies and/or applying pricing pressure, to reduce the impact of these increased expenses on the profit margins. These are far from risk-free decisions. Passing on these higher costs to customers could make their products or services less competitive in the market, while cost reduction strategies may lead to an increased exposure to risks, in an ever-changing environment.

3. Emission regulation and carbon footprint

Customers, stakeholders, and governments are demanding more responsibility and sustainability efforts from companies. As a result, supply chain operations are being directly affected by the implementation of more rigorous emission regulations and sustainability standards.

This can be particularly challenging for supply chain companies as they must balance these additional responsibilities with other ongoing industry innovations that may involve costs and changes in operational approaches. Finding the right balance is crucial to meet environmental targets while also adapting to technological advancements and remaining competitive in the market.

4. Capacity constraints

Delays, bottlenecks, and increased costs are common challenges that arise when capacity is insufficient to meet demand.

Insufficient capacity in production, transportation, or warehousing can result in backlogs and longer lead times. Delays can disrupt the smooth flow of goods and materials, leading to stockouts or missed delivery deadlines.

These delays can have cascading effects on the entire supply chain, affecting downstream operations and customer satisfaction. It is a rippling domino effect that has far-reaching implications in the industry.

These are just some of the few pressing issues in the supply chain that we face today. But where do we go from here? What specific are effective strategies to mitigate these risks and adapt to the current trying times?

II. Strategies to Address Key Concerns

Supply chain professionals have identified several risk-mitigating strategies that could address these glaring challenges.

Invest in the right supply chain technologies

Investing in the right supply chain technologies is crucial for staying competitive in the fast-changing business landscape.

Embracing technological advancements enables companies to enhance visibility, efficiency, optimize processes, and improve overall supply chain performance. They support a holistic view of the supply chains, unveiling capacity constraints, sources of optimizations that would save cost, or real-time ESG regulation markers.

From adopting advanced analytics and artificial intelligence for data-driven decision-making to implementing Internet of Things (IoT) devices for real-time tracking and monitoring, we are confident that leveraging the right technologies can revolutionize supply chain operations and lead to sustainable competitive advantage.

Implement cost-saving measures

Negotiating better contracts with suppliers, exploring alternative sourcing options, and optimizing transportation routes can help reduce expenses.

Consolidating shipments and leveraging economies of scale can also lead to significant cost savings. Moreover, optimizing inventory levels, reducing waste, and improving operational efficiency can further contribute to cost-reduction efforts.

Employ talent development strategies

Collaborating with educational institutions and industry associations helps attract and develop talent, ensuring a continuous pipeline of skilled professionals in the supply chain field. Knowledge-sharing platforms and mentorship programs further facilitate the transfer of expertise and foster a culture of continuous learning.

Embrace sustainability and reduce carbon footprint

Being up to date with the regulatory changes related to the companies’ or industry’s carbon footprints, as well as familiarity with the available solutions might be the first steps, businesses will need to take. Teams, leaders, and the organization as a whole need to be adapting to these new requirements, and embed them into the business.

Adopting greener transportation options, optimizing packaging to reduce waste, and implementing energy-efficient practices contribute to environmentally responsible supply chain operations.

Partnering with suppliers who adhere to sustainable practices further reinforces the commitment to environmental stewardship.

III. What’s next?

These aren’t new challenges to the supply chain industry, but rather factors that are continuously reshaping the industry, concomitantly with the development of new tools and digital applications.

Strategic initiatives will be how organizations can address current challenges while also positioning themselves for future success. These efforts stimulate innovation, improve competitiveness, and demonstrate responsible management of resources and the environment, ensuring business continuity amidst global and regional disruptions, and future-proofing the business in the age of digitalization.