(Photo by WinSon 5293 from Pexels)

Author: Xabier Basañez, Managing Director LATAM, Alcott Global

Today the world is passing through a major transformation in how the Supply Chain must be managed. This COVID crisis is speeding new technologies and customer patterns. Doing what you’ve always done—even if you do it very well—is no longer acceptable. Under pressure to contain costs and produce results despite all challenges.

Under today’s pressure to contain costs and produce results, you must transform rather than simply improve your operation. That means adopting the methods, technologies, and processes that will make your organization “best in class.”

You need to select and establish which are the best practices to follow.

What makes a supply chain organization best in class? The answer will vary for each company, but Leader firms know that orders-whether they are replenishment, customer, or new products– must be delivered complete, accurate, and on time. This must be done consistently; reliability is a hallmark of best-in-class supply chains. These best companies know they use supply chain best practices to effectively manage global supply chains.

We can summarize the Supply Chain Management Best Practices like the ones presented by LTD Management, which is summarized as follow:

1. Increase inventory velocity:

Inventory must move quickly; turns should be high. It must flow from suppliers or manufacturing sites to customers. Being inventory rich and cash poor is not a sound approach. This is especially so for A items and many B items. Products sitting in warehouses should be limited as much as possible.

2. Implement lean logistics/supply chain management:

Lean logistics complement supply chain management. Both emphasize pulling, not pushing, products through the supply chain. Both recognize and lean removes–the waste created by excess inventory and time and the need for supplier performance.

3. Improve supplier performance:

Success begins with supplier performance. They must deliver quality items and do it complete, accurate, and on time. Collaboration is important. Whether the products are finished goods or materials for factories, the need for strong supplier performance is there. Clear monitoring and improving the performance of the Suppliers through SLA should be the objective.

4. Compress cycle time:

Cycle time runs from the time the need for a product-now or replenished-is determined and goes until it is delivered to the customer or to the store. The length of global supply chains adds to the challenge.

5. Maximize inventory yield:

There is a window of opportunity to get the maximum price, the maximum, yield for products. Miss that window and companies face reduced pricing and profit margins. Leaders understand this in using best practices.

6. Utilize meaningful metrics:

There are numerous measures for companies and their supply chains. Many are measures for the sake of metrics with little meaning to corporate-level executives or with little value in really measuring supply chain performance. Meaningful metrics means leading indicators, which are orders delivered complete, accurate, and on time and time related-such as days of inventory on hand, cycle time, and others.

7. Segment the supply chain:

Too many firms have one supply chain approach for everything. This monolithic approach handicaps performance diverts resources and creates static noise from external and internal sources that distracts the supply chain organization. The best segment their supply chain and focus performance where it is most beneficial. Instead of practicing one-size-fits-all supply chain management, they tier based on profit margin or days of inventory or similar important ways.

8. Employ supply chain technology:

Supply chain execution technology is important to managing a global supply chain. The new industrial revolution 4.0, AI, and the IoT are technologies that will elevate the Supply Chain. The technology should provide visibility throughout the entire supply chain. Tracking and tracing are nice, but it misses the important factor. It is not about the container or pallet of the product. The key issue is to manage the customer, purchase, or build order through to delivery. Technology, especially when tied with collaboration, can provide that.

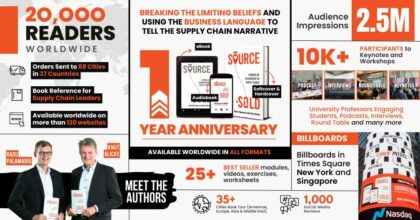

Source: Best Practices in Supply Chain by Xabier Basañez | LinkedIn