Rosemary Coates is the Executive Director of the Reshoring Institute, a Non-Profit collaboration with nine universities across the U.S. She is also the President of Blue Silk Consulting, a Global Supply Chain consultancy. She is an Amazon.com Best Selling author with 5 global supply chain books including: “The Reshoring Guidebook” and “42 Rules for Sourcing and Manufacturing in China” She has been a management consultant for 25 years, helping over 80 global supply chain clients. She serves on the Board of Directors of Kinetic River and the University of San Diego Supply Chain Management Institute. And teaches Global Supply Chain Strategy at UC Berkeley.

Listen to the full discussion here:

-

- Listen on Stitcher

Connect with the Guest:

Rosemary Coates: LinkedIn

Some of the highlights from the podcast:

- How the manufacturing sector is dealing with the trade war and the pandemic

- Hurdles of moving out of China, pandemic or not

- Case studies – stories of success and failure in reshoring

- Why mathematics is needed in operating production lines

- How politics can affect the phase of decoupling

Show notes:

- [01:11] What’s the current status of decoupling? Is change happening now? Is it going to happen in six months, 12 months, 18 months, or longer plans, how is it going?

- [04:16] We’re seeing a pretty significant wave in companies considering decoupling or designing a different kind of global strategy. There are all kinds of pathways, but clearly, a change is in the wind for sure.

- [04:55] How do you see things in five years down the line? How much of China for China is made in China? How much is exported from China to other markets? How much is US for US? How do you see these dynamics playing out?

- [06:32] Executives now are finding that a lot of their customers are in Asia. Asia is where growth is happening. It’s not happening that much in the US or Europe, but it’s all over Asia. So it only makes sense to at least keep part of your manufacturing in Asia.

- [07:25] Where do you see lower-cost manufacturing locations that will benefit after these conflicts and trade wars? Is it Southeast Asia, Mexico, Europe, or Northern Africa?

- [09:59] What we really want to develop is advanced manufacturing, advanced skills for the manufacturing environment and leave the low skilled, low-cost labor jobs in a low-cost country.

- [11:36] If you talk about manufacturing electronics, which is a very complex ecosystem, the manufacturing plant is easy to take somewhere else but the whole ecosystem around that plant is not that easy to place somewhere else. Especially at the same time with a trade war. So how will this play out in the long term?

- [16:43] Supply chain people got to develop on and think strategically at a higher level instead because traditionally we’ve been really focused on execution, now it’s time to think about strategy.

- [17:10] I saw a statistic and I wanted to run it by you, I think there was like 30% or 35% of companies already moving out of China in the middle of COVID-19. What are some of the hurdles to do that?

- [20:43] I could go on and on about leaving China, but the thing that I would want people to take away is to understand that it’s not going to be as easy as they think, and they probably need help to extract themselves from another country. So, they need to be careful about it.

- [21:03] Tell us maybe some case studies, cause I know that you work with some global brands. So maybe give us one or two or three examples that you’ve helped in recent times, what worked, what didn’t work, and what was challenged?

- [23:05] Waterlogic, even though they had an extensive sales operations across the US they didn’t have any manufacturing sites. So we help them over about a year to not only find the best location for them, but also to look at labor costs, tax incentives, and government sent incentives at the state and local levels.

- [26:46] Companies are going to try to move their manufacturing somewhere else or bring it back to the US. It’s a big project and it’s hard work and you can’t just snap your fingers and make it happen. It really takes effort.

- [28:02] What new skills, even if you do reshoring in these more expensive markets or developed markets, what new skills will they need?

- [30:29] If you plan to be in an industrial environment in your life, whether you’re the CEO or the Senior Executive in Supply Chain, or you’re a worker, you need to know mathematics. So it’s surprising how much math you actually need in order to operate on most production lines.

- [32:18] Vietnam only has 90 or a hundred million people and there isn’t any factory capability or not much left. And the other thing that we found was even though the labor cost is lower in Vietnam, the productivity rate was lower.

- [33:52] You’re sitting in the US I don’t want to get very political, but depending on your election that is coming up and the results of the elections, do you see a shift in the pace of decoupling?

- [35:28] There are so much politics and economics involved with any decision that’s made with leadership and it’s important that we have a voice and keep guiding our leaders in what’s needed in global manufacturing.

About the Host:

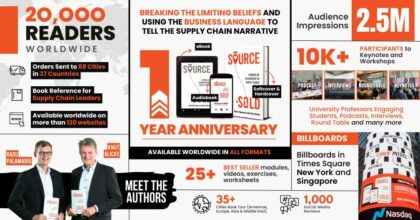

The host, Radu Palamariu is the co-author of “From Source to Sold – Stories of Leadership in Supply Chain”. He has been named one of the top 3 Global Supply Chain Influencers on LinkedIn and was featured in Forbes, Bloomberg, WEF, Bangkok Post, and MIT Supply Chain Talent magazine. Radu invites executives to share stories and perspectives around technology, logistics, e-commerce, supply chain, and manufacturing, and their views on how the future will look.

Alcott Global connects and upgrades the supply chain ecosystem by finding the right talent through executive search, developing talent through learning solutions, and meeting supply chain technology needs through a comprehensive crunch base marketplace.

The supply chain executive search has been our focus since the very beginning, offering recruitment services for top-tier supply chain roles at every level of the end-to-end supply chain: plan, source / procure, make, and deliver. Our consultants have years of experience in placing top talent, in North America, LATAM, Europe, the Middle East & Africa, and APAC, and besides speed, one of our biggest strengths is our network within the supply chain industry, and we capitalize on it to find the best solutions.

Through the years, we have grown as an organization and our offerings with it. One of our initiatives, the learning solutions- training and supply chain academy, is focused on transforming leadership- self-leadership, executive presence, influence capital, and business acumen. Through Supplify, we aim to match corporations with the top technology companies to solve their supply chain and logistics challenges with a focus on innovation and digital transformation.

We are in constant touch with the leaders in supply chain, inviting them to inspire the supply chain professionals in thought-provoking podcast episodes and events, and showcasing what is possible at the yearly Leaders in Supply Chain Awards.

Related Episodes:

#89: Thierry Malleret Managing Partner of Monthly Barometer

#90: Konrad Bauer VP Supply Chain and Operations at Thermo Fisher Scientific

#91: Knut Alicke Partner at McKinsey and Head of Supply Chain Europe