Lorenzo has 27 years of experience with multinationals and startups in the ICT/ HITECH, FMCG, industrial/consumer electronics, fashion, and retail sectors. In Huawei he is an executive advisor on strategy and global operations, sharing knowledge to improve supply chain performance and leadership behaviors, with a focus on continuous growth in digital transformation, influencing skills and cultural awareness across different regions and functions.

Prior to his current role, he had P&L/leadership experience across supply chain roles in Italy, UK and Switzerland. And he is also a member of the MIT Technology Review Global Panel, providing input upon request on topics around business and technology.

Listen to the full discussion here:

- Stream by clicking here.

- Download as an MP3 here.

Connect with the Guest:

Lorenzo Fornaroli: Linkedin | Twitter

Some of the highlights from the podcast:

- How Huawei is handling the Trade War situation.

- What is the low hanging fruit tech-enabled solution to make an impact on your supply chain?

- Challenges that Huawei has in their operations

- Why are information sharing and setting clear requirements important to an LSP partnership?

- Machines will replace humans but humans create machines – the future of work and automation

- Differences between Western culture and Asian culture – how it was for Lorenzo to adapt to Huawei

Show notes:

- [02:00] What strategies do Huawei deploy to mitigate supply chain risks that are arising from the current trade war and for future trade wars?

- [03:40] “We are looking at the physical distribution and understand where are the areas where we can have an impact and areas where we can improve the level of our operations.”

- [04:20] “We are building a lot of hypothetical solutions to make sure that if plan B does not materialize, we have a plan C.”

- [06:00] Is it possible to totally mitigate any sort of risk like this trade war?

- [06:47] You should have a solid plan to address everything- risk management and contingency plan. [09:40] Which of the digital technology made the biggest impact on your supply chain?

- [10:55] The type of purpose you have will guide your selection of the digital transformation aspects you want to put in place.

- [12:39] Automation is a challenge somehow, not on Huawei, but a challenge in general because it means a lot of investments, solid long term relationship with suppliers and having a clear ROI conversation.

- [13:40] “Having our own system means we control our network and we can build models because we know exactly the flow of our goods.”

- [15:43] Where would you see some low-hanging fruit in terms of technology that can be used fairly?

- [16:06] I would say low-hanging fruit could be access to data because data allows you to take decisions which you can also extend to the sales guys and you can use data to understand exactly how to manage the flows on your warehouses.

- [17:18] See what data you already have and what you can do on that data.

- [18:49] Are there specific pain points left regarding logistics or supply chain? And if so what are the biggest one you have in Huawei right now?

- [20:06] Scalability depends on the type of products you’re handling, the volumes you have and your relationship with your supplier.

- [21:17] We need to nurture our relationship so that it can turn into a long term partnership and not just a contractual relationship,

- [23:14] What would be some of the elements for a successful and sustainable partnership-driven relationship?

- [24:21] Make sure you have set your requirements very clearly and measure what is really relevant and pertinent to your business.

- [29:05] How do you show that you are confident and serious to your partners?

- [32:26] The more information you have shared, the more you show your trust in the supplier and the more you are assessing them with the right metrics.

- [34:20] There is a bigger human component between a shipper and a buyer, it is not just numbers, performance and contract but there is also a certain level of empathy that has to transpire in the relationship.

- [37:40] What is your perspective on automation and people being displaced on the procurement and planning side?

- [40:55] While we see a part of roles being lost and sacrificed, there are also other roles that are coming out that didn’t exist before.

- [44:20] You need to fight self insecurity so you need to skill up yourself and continue to learn.

- [46:50] How did your experience in China changed the way you think?

- [51:08] I have learned the value of working in a big company and having independence on how you invest your money and the value of listening.

- [54:54] What are the important soft skills in the next 10 to 20 years the supply chain industry?

- [55:28] In my opinion, it is the ability to learn through observing.|

- [59:10] The last one is building a relationship with people. Machines will take out the human components of a relationship, and there are certain ones that need to exist along with the human value.

Quote from the Episode:

About the Host:

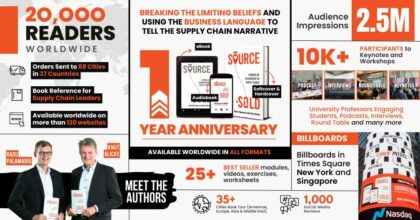

The host, Radu Palamariu is the co-author of “From Source to Sold – Stories of Leadership in Supply Chain”. He has been named one of the top 3 Global Supply Chain Influencers on LinkedIn and was featured in Forbes, Bloomberg, WEF, Bangkok Post, and MIT Supply Chain Talent magazine. Radu invites executives to share stories and perspectives around technology, logistics, e-commerce, supply chain, and manufacturing, and their views on how the future will look.

Alcott Global connects and upgrades the supply chain ecosystem by finding the right talent through executive search, developing talent through learning solutions, and meeting supply chain technology needs through a comprehensive crunch base marketplace.

The supply chain executive search has been our focus since the very beginning, offering recruitment services for top-tier supply chain roles at every level of the end-to-end supply chain: plan, source / procure, make, and deliver. Our consultants have years of experience in placing top talent, in North America, LATAM, Europe, the Middle East & Africa, and APAC, and besides speed, one of our biggest strengths is our network within the supply chain industry, and we capitalize on it to find the best solutions.

Through the years, we have grown as an organization and our offerings with it. One of our initiatives, the learning solutions- training and supply chain academy, is focused on transforming leadership- self-leadership, executive presence, influence capital, and business acumen. Through Supplify, we aim to match corporations with the top technology companies to solve their supply chain and logistics challenges with a focus on innovation and digital transformation.

We are in constant touch with the leaders in supply chain, inviting them to inspire the supply chain professionals in thought-provoking podcast episodes and events, and showcasing what is possible at the yearly Leaders in Supply Chain Awards.

Related Episodes:

Episode #09: Chang Wen Lai CEO at Ninja Van

Episode #13: Damien Dhellemmes Country President for Schneider Electric Singapore

Episode #45: Paul Graham Chief Supply Chain Officer of Woolworths Group