Massimo Andolina is the SVP Operations at Philip Morris International (PMI) since 2018. He joined the company in 2008 as Director Operations Planning and served in various VP roles thereafter, including VP PMI Business Transformation. Prior to joining PMI, Massimo held a variety of international positions in strategic marketing and general management for Tetra Pak and in operations for R.J. Reynolds.

PMI is a leading international tobacco company working to deliver a smoke-free future and evolving its portfolio for the long-term to include products outside of the tobacco and nicotine sector. Since 2008, PMI has invested more than USD 9 billion to develop, scientifically substantiate and commercialize innovative smoke-free products for adults who would otherwise continue to smoke, with the goal of completely ending the sale of cigarettes.

Listen to the full discussion here:

Connect with the Guest:

Massimo Andolina: LinkedIn

Some of the highlights from the podcast:

- Inflection points in Massimo’s career

- PMI’s transformation from a tobacco to an electronics company

- From a manufacturing-centric to a customer-centric supply chain

- What worked and what didn’t in the transformation process

- Why the ability to learn and unlearn is key to PMI’s transformation

- Leap frogging supply chain and change management

Show notes:

- [01:00] Tell us about your inflection points. What brought you to where you are today, which we might not see immediately from your CV?

- [03:31] “I lived through the 1998 financial crisis in Russia and that was probably the first major inflection point in my career.”

- [06:29] “Supply chain is very exciting. Supply chain is that place where the marketing promise of a wonderful experience for consumers is made into reality.”

- [9:12] “PMI decides to formally kick off its transformation. Making an external commitment, after many years of preparation, to the entire world that we will deliver a smoke-free world.”

- [12:13] “In just six years, we have managed to convert 21.2 million people from being smokers to adopting IQOS and abandoning smoke.”

- [14: 50] “I’m looking at a variety of things that need to change if we are to evolve the supply chain to where the business needs it”

- [16:26] “We realized that we needed to leapfrog in the use of data, technology, and digital tools, across all of the activities that we were running if we wanted to manage to fulfill the expectations that the business had for this evolution.”

- [19:13] “The key element that we had to shift was our ability to learn and unlearn.”

- [20:26] “The fundamental element in a transformation of this magnitude is to be ready to put behind what keeps you comfortable and to open yourself up to learn rapidly what is necessary for the journey.”

- [21:24] Can you give us some even more tangible case studies of how you did that change management in the minds of the organization and of the people, which is usually the hardest to change?

- [24:46] “In supply chain, we had to radically transform the processes. We realized that we needed to leapfrog in because we were largely working manually and were largely working on a b2b model. We needed to rapidly evolve the technology that we use.”

- [28:47] If you were to do it all over again, knowing what you know today, what would you do differently?

- [32:45] “In the moment of crisis, people tend to go back to the bad habits.”

- [34:16] What principles are you using when hiring or attracting talent?

- [35:28] “We also wanted to bring in people from the outside that could bring the knowledge and the experience, having lived it on their skin, in order to help us accelerate the journey.”

- [39:35] “Culture is about the behaviors that people display and what they intrinsically know that is expected. And so what you said is absolutely right. Soft skills are the hard skills.”

- [40:19] What would be one piece of advice or principle that has been most helpful to you?

- [42:04] “Wins he who wins himself. Those moments of big change are the moments in which you need to win over yourself and go for it.”

Quotes from the Episode:

Soundbite from the Episode:

About the Host:

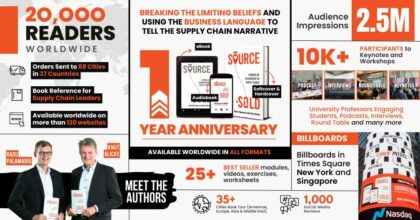

The host, Radu Palamariu is the co-author of “From Source to Sold – Stories of Leadership in Supply Chain”. He has been named one of the top 3 Global Supply Chain Influencers on LinkedIn and was featured in Forbes, Bloomberg, WEF, Bangkok Post, and MIT Supply Chain Talent magazine. Radu invites executives to share stories and perspectives around technology, logistics, e-commerce, supply chain, and manufacturing, and their views on how the future will look.

Alcott Global connects and upgrades the supply chain ecosystem by finding the right talent through executive search, developing talent through learning solutions, and meeting supply chain technology needs through a comprehensive crunch base marketplace.

The supply chain executive search has been our focus since the very beginning, offering recruitment services for top-tier supply chain roles at every level of the end-to-end supply chain: plan, source / procure, make, and deliver. Our consultants have years of experience in placing top talent, in North America, LATAM, Europe, the Middle East & Africa, and APAC, and besides speed, one of our biggest strengths is our network within the supply chain industry, and we capitalize on it to find the best solutions.

Through the years, we have grown as an organization and our offerings with it. One of our initiatives, the learning solutions- training and supply chain academy, is focused on transforming leadership- self-leadership, executive presence, influence capital, and business acumen. Through Supplify, we aim to match corporations with the top technology companies to solve their supply chain and logistics challenges with a focus on innovation and digital transformation.

We are in constant touch with the leaders in supply chain, inviting them to inspire the supply chain professionals in thought-provoking podcast episodes and events, and showcasing what is possible at the yearly Leaders in Supply Chain Awards.

Related Episodes:

#125: Heineken SCM, IoT and 3D Printing