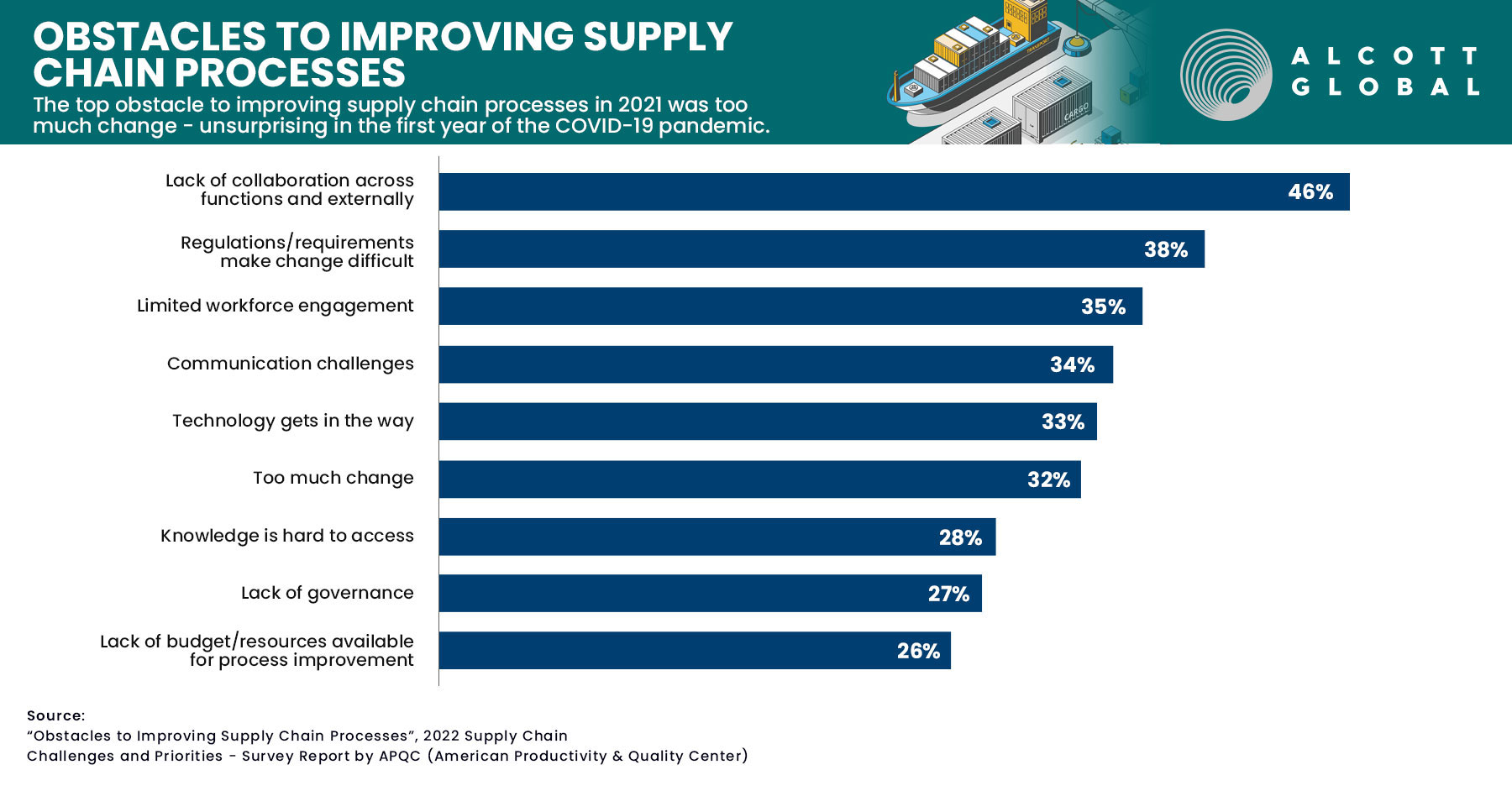

In a survey carried out by APQC in January 2022, as research in order to learn about organizations’ supply chain management priorities, performance, and trends.

In 2021 the top obstacle was too much change, which wasn’t especially surprising given the pandemic and was replaced in 2022 by the lack of collaboration. Difficulties in improvements due to regulations/requirements partly reflect the speed with which supply chains are changing, often faster than the policymakers can keep up.

There’s no doubt that global supply chains involve a great deal of data, transactions, and physical material flowing between suppliers, enterprises, contract manufacturers, and logistics providers. Although too much change dropped to the sixth place in the 2022 survey, all of these obstacles are the ripple effect of changes and disruptions that accelerated in the period 2020-2021, supply chains remaining fragmented, with different departments operating on different systems, and different versions of the truth.

Fixing collaboration will take effort on both aligning technologies and KPIs, also improving communication and the processes that support it. There’s an inseparable trio Technology-People-Processes, that needs to be addressed in parallel for improving collaboration: “When the technology fails and the processes are disrupted if we have the right people, we can still support the business. But if you don’t have the people, the processes and the technology are not going to get your customer what they need.”- Emer Cunningham, title, function – episode #113 – Leaders in Supply Chain & Logistics Podcast

Most changes generate a sense of unease because they push employees out of their familiar and comfortable territory and communication could change the unease to excitement and employees’ engagement needs to be at the heart of a successful change management plan.

What do you think will be the challenges in improving the supply chain processes by the end of 2022?