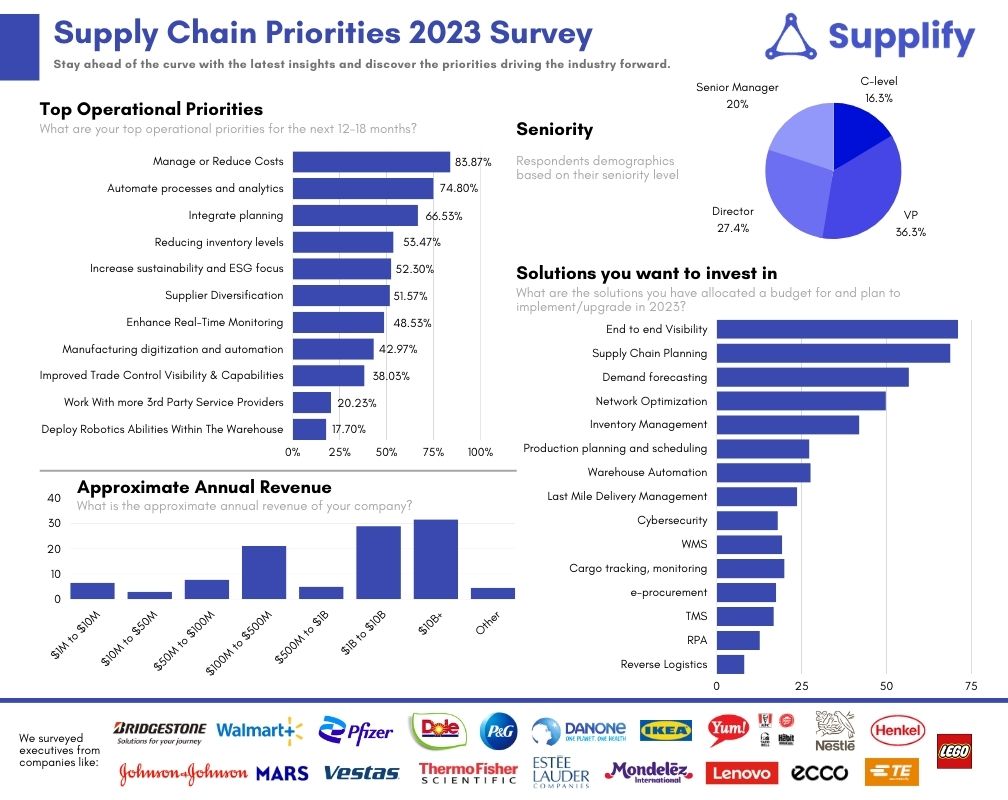

As we enter the year 2023, the global supply chain industry is experiencing a period of rapid transformation. Driven by the need to stay competitive in an ever-changing market, companies are looking for ways to optimize their supply chain operations, reduce costs, and increase efficiency. We’ve recently conducted an industry survey, part of Supplify initiatives, among some of the biggest consumer brands. In this post, we will explore the top five priorities for supply chain management in 2023 and the top five solutions that companies should invest in to achieve these priorities according to results from the survey.

Top Operational Priorities

1. Managing or Reducing Costs (83.87%)

In the current economic climate, companies are facing significant pressure to manage or reduce costs. Supply chain management can play a critical role in achieving this goal. One of the ways to reduce costs is to optimize transportation, warehousing, and inventory management. Companies can reduce transportation costs by using optimized routing strategies, consolidating shipments, and leveraging technology like autonomous vehicles. By optimizing warehouse operations, companies can reduce handling costs and increase throughput. Additionally, reducing inventory levels can help companies reduce carrying costs and improve cash flow.

2. Automate Processes and Analytics (74.80%)

Automation is rapidly transforming the supply chain industry. Companies are adopting technologies like robotics, drones, and artificial intelligence to automate processes, increase efficiency, and reduce costs. Automation can help companies streamline processes, reduce errors, and increase productivity. By leveraging analytics and machine learning, companies can gain insights into their supply chain operations, identify inefficiencies, and make data-driven decisions.

3. Integrate Planning (66.53%)

In today’s interconnected world, supply chain planning requires a collaborative approach. Companies need to integrate planning across different departments, partners, and suppliers to achieve a seamless flow of goods and services. By sharing information and coordinating activities, companies can optimize their supply chain operations, reduce lead times, and improve customer service.

4. Reduce Inventory Levels (53.47%)

Inventory management is critical to supply chain management. Excess inventory can tie up capital, increase costs, and reduce profitability. Companies need to optimize inventory levels to balance supply and demand and minimize the risk of stockouts. By leveraging demand forecasting and inventory management tools, companies can improve their inventory planning and reduce excess inventory.

5. Increase Sustainability and ESG Focus (52.30%)

As sustainability becomes an increasingly important issue for customers, investors, and regulators, companies must focus on reducing their environmental footprint and increasing their social impact. Companies can improve their brand reputation, attract customers, and achieve long-term success by adopting sustainable practices and implementing ESG (Environmental, Social, and Governance) criteria.

Top Industry Solutions

Now that we have explored the top five priorities for supply chain management in 2023, let’s look at the top five solutions that companies are choosing to invest in to achieve these priorities.

End-to-End Visibility: End-to-end visibility is critical for supply chain management. Companies need to be able to track their goods and services from the source to the final destination. By implementing visibility solutions like RFID, GPS, and blockchain, companies can gain real-time insights into their supply chain operations, identify bottlenecks, and improve customer service.

Supply Chain Planning: Supply chain planning tools like demand forecasting, capacity planning, and production scheduling are essential for optimizing supply chain operations. By using these tools, companies can improve their forecasting accuracy, reduce lead times, and minimize stockouts.

Demand Forecasting: Demand forecasting is a critical component of inventory management. By leveraging historical data, market trends, and customer behavior, companies can accurately predict demand and optimize inventory levels. By investing in demand forecasting tools, companies can reduce excess inventory, improve cash flow, and increase profitability.

Network Optimization: Network optimization is essential for reducing transportation costs and improving customer service. By using network optimization tools, companies can optimize routing, reduce transit times, and improve delivery performance. This can help companies reduce costs, improve customer satisfaction, and gain a competitive advantage.

Inventory Management: Inventory management is a critical component of supply chain management. By optimizing inventory levels, companies can reduce costs, improve cash flow, and increase customer satisfaction. Inventory management tools can help companies track inventory levels, identify slow-moving items, and optimize reorder points. By investing in inventory management solutions, companies can reduce excess inventory, minimize stockouts, and improve their overall supply chain efficiency.

In conclusion, as we enter 2023, supply chain management is evolving rapidly, and companies need to adapt to stay competitive. Managing or reducing costs, automating processes and analytics, integrating planning, reducing inventory levels, and increasing sustainability and ESG focus are the top priorities for supply chain management in 2023. By investing in solutions like end-to-end visibility, supply chain planning, demand forecasting, network optimization, and inventory management, companies can achieve these priorities and optimize their supply chain operations. Companies that prioritize supply chain management and invest in the right solutions will be well-positioned to succeed in the fast-changing business environment of 2023 and beyond.